Aerospace

Partnering with Commercial and Military Aerospace to provide coating removal, composite bond prep, tool cleaning, and MRO applications.

Foundry

Offering a variety of foundry equipment & process materials for melt departments, mold & core making, cleaning rooms, and safety equipment.

Metal Finishing

Metal finishing process equipment including wet, dry and wheel blast equipment, vibratory finishing, grinding equipment, dust collection and more.

Blasting Abrasives

Midvale offers a wide selection of high quality angular, round and soft blasting abrasives; most of which are made in North America.

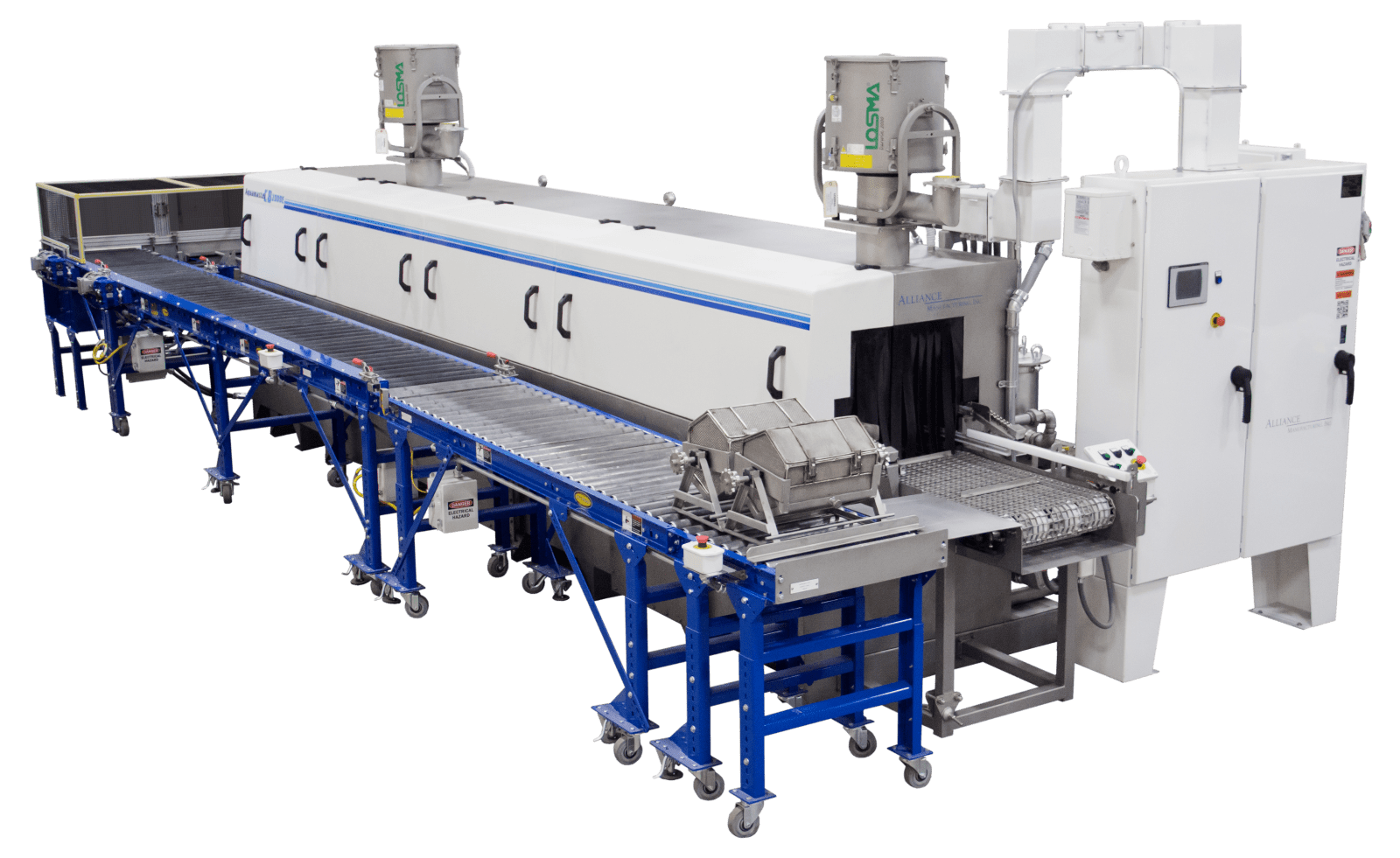

Parts Washing

Midvale offers Industrial Grade Parts Cleaning Equipment Including Aqueous Spray Washers and Ultrasonic Parts Washers.

Industrial Coating

Industrial grade painting & coating equipment, spray guns, spray pumps, paint booths, paint equipment parts & accessories.

Engineered Industrial Solutions and Process Development

Midvale Industries specializes in engineered process solutions to ensure you continue to produce high quality products. Our team works with you to develop a manufacturing process that is economical, produces high quality metal components and implements an efficient work-flow to maintain high levels of productivity in your facility. We strive to be your personal consultant and to find the right process for your project.

Benefits of Partnering With Midvale

Over 120 Years of Proven Process Development

Long-Term Customer Relationships

Continuous Process Improvement

Our Process

At Midvale, we provide a personal approach to ensure your process is functioning at an effective and productive manner. We analyze your system, and work with you through testing to develop a complete system that will attain goals within your budget.

Our sales team is backed with years of industrial knowledge and training so that we may assist you in expanding your business. Each sales person goes through extensive technical training on a consistent basis so that we can continue to be up to date on the latest industry trends, best practices,and safety regulations.

Let our team of technically trained consultants help you discover the best solution for your application.

What Our Customers Say

Our Services

Lab & Process Testing Services

Midvale Industries Laboratory Services provides customers with the ability to explore the many types of finishes available to them through laboratory testing with a variety of abrasives, chemicals, and equipment without slowing production at their facility.

Capabilities: Dry & Wet Blasting, Vibratory Finishing, Ultrasonic or Spray Parts Washing, Surface Finishing Testing (RA & PA), Blast Media Work Mix Screening

Contract Job Shop Services

FTI Tulsa is our job shop that provides a range of services including cleaning, mass finishing, and more. FTI is capable of processing small and large batch parts finishing. We provide quality service, quick turn-around times, competitive pricing and local delivery.

Capabilities: Profiling, Deflashing, Deburring, Degreasing, Descaling, Cleaning, and Peening

Equipment Repair Services

Midvale Industries provides in house and outbound service and repairs for various metal finishing equipment. Our team of technicians are backed by years of training, experience and stocked parts room to get your equipment up and running quickly.

Capabilities: Maintenance and Repair of Portable Blast Equipment, Paint Sprayers, Power Washers, Wheel Blast Equipment, Vibratory Finishing Machines, Parts Washers, and More